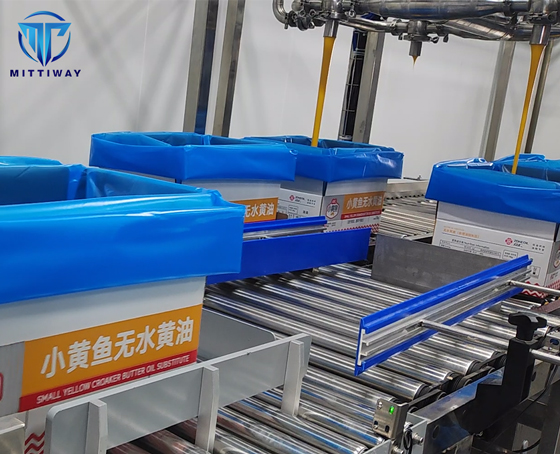

Automated packaging line for fermented raw milk butter

(7210 review)

Category: Margarine packaging line

- Description

The Carton Erector and Bag Inserter Machine work in tandem, followed by precise metering via Automatic Filling, instant freshness locking via Automatic Sealing Machine, and secure sealing via Case Sealer. Finally, Robotic Arm Palletizing intelligently palletizes the milk. The entire process is automated and requires no human contact, preserving the original freshness and aroma of fermented raw milk while maintaining both efficiency and quality.

The core advantages of automated packaging for fermented raw milk butter lie in three dimensions: safety, efficiency, and quality, as detailed below:

1. Enhanced Safety: No direct human contact throughout the entire process, reducing the risk of secondary contamination.

Equipment uses food-grade contact materials, meeting food safety standards.

Full data traceability ensures clarity at every stage, from filling to palletizing.

2. Significantly Increased Efficiency: Multiple machines work collaboratively, completing thousands of packages per hour, far exceeding manual efficiency.

Carton forming, bagging, filling, sealing, box sealing, and palletizing are all automated, requiring no human intervention.

Robotic palletizing equipment can operate continuously 24 hours a day, reducing production interruption costs.

3. Consistent and Stable Quality: Automated filling equipment precisely controls the quantity, resulting in minimal weight error and uniform quality in every batch.

Automatic sealing machines instantly lock in freshness, better isolating the product from air and moisture, preserving the original flavor and smooth texture of the fermented raw milk.

Standardized packaging specifications and sealing strength eliminate individual differences inherent in manual operations.

4. More Controllable Costs In the long run, it can reduce costs related to recruitment, training, and management of personnel.

It reduces losses such as raw material waste and packaging damage caused by human error.

Search Keyword

Category

Latests

-

5-25kg Bucket-Packed···

(687 review)

-

10-25KG Animal Butte···

(1230 review)

-

Automated packaging ···

(7211 review)

-

20kg water-free ghee···

(12089 review)

-

10-25kg waterless gh···

(12193 review)

-

Margarine and butter···

(12227 review)