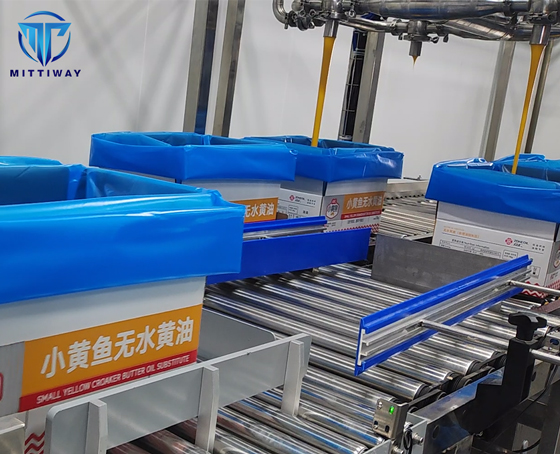

20kg water-free ghee box packaging intelligent packaging line

(12030 review)

Category: Margarine packaging line

- Description

When 20kg water-free ghee needs to be efficiently converted into boxed finished products, this automated packaging line that combines precision and speed is redefining production efficiency with the advantage of unmanned intervention in the entire process.

At the starting point, Carton Erector takes the lead in starting - the flat carton board is automatically opened, folded, and sealed under the precise operation of the robotic arm, and instantly formed into a standardized box body, laying a solid foundation for subsequent filling and avoiding size deviations and efficiency bottlenecks caused by manual folding.

Then, Bag Inserter Machine seamlessly connects: the pre-prepared food-grade inner bag is smoothly fed into the formed carton, and the bag mouth is accurately opened, which not only ensures the perfect fit between the inner bag and the box body, but also reserves safe operating space for the subsequent filling process, eliminating the risk of contamination that may be caused by manual bag placement.

The core filling process is controlled by Automatic Filling: the sensor senses the position of the inner bag in real time, and the metering pump accurately injects oil according to the standard dosage of 20kg, and the liquid level error is controlled within ±50g. Whether it is the change in the fluidity of ghee or the dynamic adjustment of the filling rhythm, the system can automatically adapt to avoid spills and inaccurate metering.

After the filling is completed, the Automatic Sealing Machine responds quickly: the inner bag is heat-sealed, the seal is flat and firm, and it effectively isolates air and moisture; then the box cover is automatically aligned to prepare for the final sealing. There is no need for manual contact with the material throughout the process, which meets the food production hygiene standards.

Finally, Case Sealer puts a full stop to the entire process - the tape is accurately pasted along the seams of the carton, and the upper and lower seals are formed in one time, which is strong enough to cope with storage stacking and long-distance transportation. From the formation of the empty box to the completion of the sealing, the processing time of a single box is shortened to less than 15 seconds, and 240 boxes can be output stably per hour, which perfectly adapts to the production capacity requirements of medium and large-scale production.

This automated packaging line, designed specifically for 10-25kg of water-free ghee, integrates the entire process of "forming - bagging - filling - sealing - box sealing". It not only ensures the hygiene and safety of food packaging and accurate measurement, but also reduces costs and improves stability by reducing manual intervention. It has become a core driver for ghee production companies to reduce costs and increase efficiency.

Search Keyword

Category

Latests

-

5-25kg Bucket-Packed···

(622 review)

-

10-25KG Animal Butte···

(1179 review)

-

Automated packaging ···

(7158 review)

-

20kg water-free ghee···

(12031 review)

-

10-25kg waterless gh···

(12137 review)

-

Margarine and butter···

(12175 review)